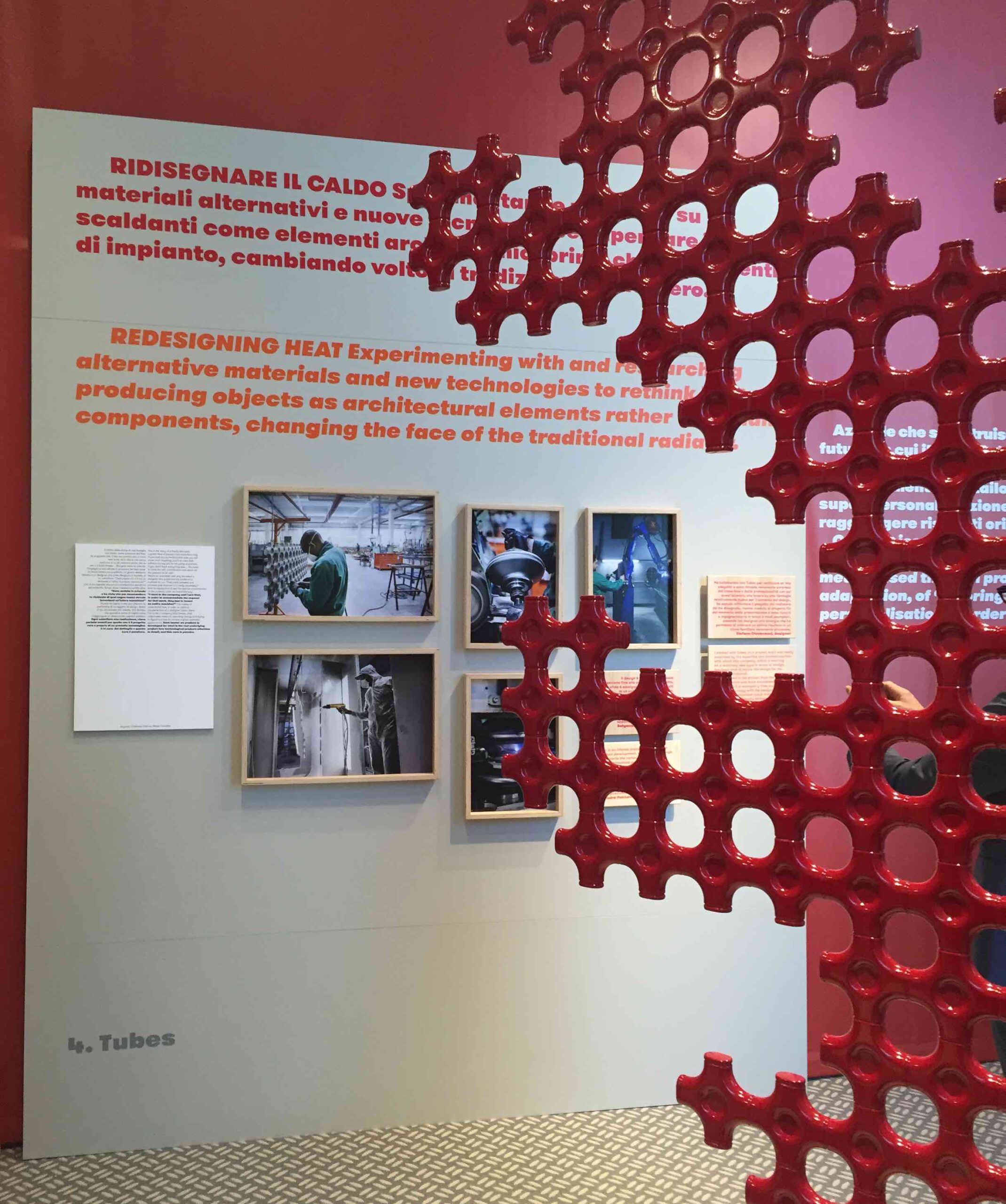

Since it was established in 1992, the brand has continued to astound and mesmerise with unusual products and ground-breaking innovations, with a perpetually changing formal language.

Tubes has always been committed to shaping heat via design.

Thanks to its experimental approach and to a sequence of native technical inventions, Tubes has transformed the very concept of conventional radiators: from simple technical systems on the margins of the domestic space into items of interior décor with a notable personality, stars of the interior aesthetic styling.

For Tubes, shape does not follow function:

it is function itself.

Its visionary and radical approach has been rewarded by the most significant and prestigious international design and contemporary art institutions.

Tubes products are included in the permanent collections on exhibit at the Centre Pompidou in Paris, the International Design Museum in Munich and the MAC (Musée d’Art Contemporain) in Montreal.

Among the most authoritative awards obtained in recent years, mention must be made of the ADI Compasso d’Oro 2018, the Design Europa Award 2018, the Salone del Mobile Award 2016 and the Menzione d’Onore (Honourable Mention) at the ADI Compasso d’Oro 2016.

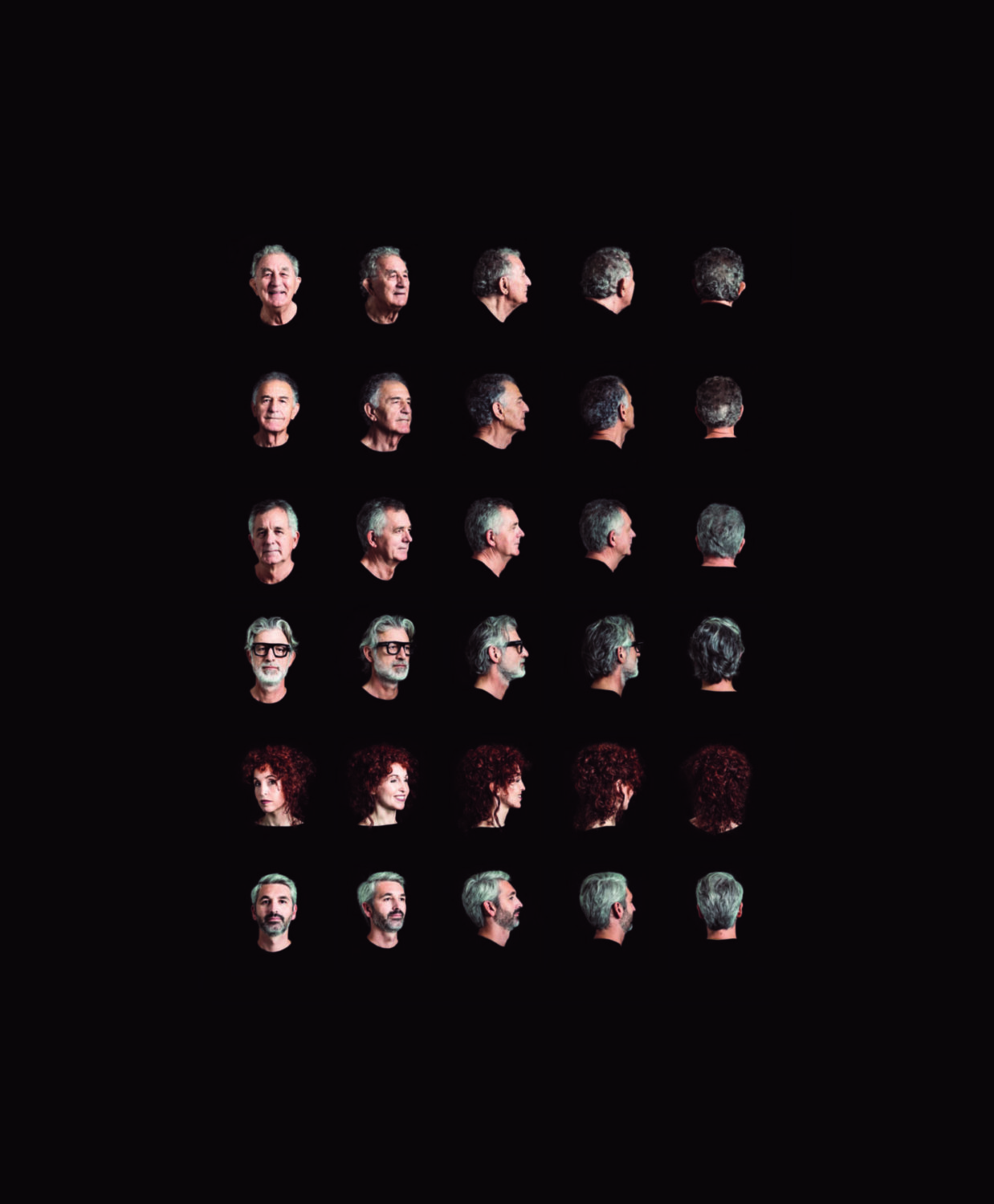

However, the story of Tubes is above all the story of the Crosetta family, who founded and to this day continues to run the company with the same passion as at the outset, together with the men and women who have contributed day-in day-out to making Tubes the success that it is today: a brand that is synonymous with design and creativity, in Italy and across the globe.

Tubes values are also those pertaining to their roots, to a local territory and inner landscape, of the entire production cycle which has always been concentrated in the historic company headquarters in Resana, of a short and controlled supply chain that makes the concepts of responsibility, faith and reliability concrete.